The main function of the signal lines laid inside the electric locomotive is to transmit various signals of the locomotive, including emergency braking in an emergency. Therefore, the protection of the signal line is particularly critical, which is related to the safety of the motor vehicle operation and the safety of life and property of the motor vehicle passengers.

Although the signal line has a layer of shielding protection, because the motor car will vibrate during the running process, the continuous friction between the signal line and the body will lead to disconnection. In addition, there are many signal lines, which are very messy when laying. In response to these problems, our engineers designed a product specially designed to protect the signal line, so that the signal line laid inside the motor car can be well protected in the complex electromagnetic environment and harsh environment.

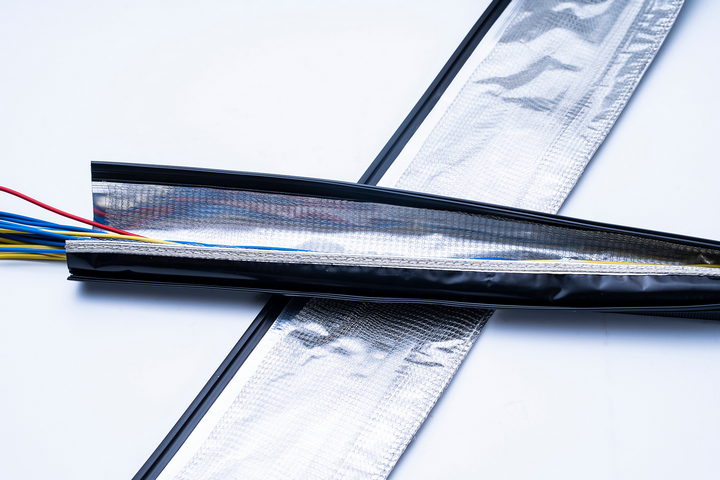

Shielding sleeves came into being at this time. The outer layer of the shielding protection sleeve is an insulating layer, which has both flame retardant performance and friction resistance; the inner layer is a shielding mesh layer, which has the functions of shielding and electrostatic diversion. The outer layer of the protective sleeve is a layer of textile, which has a good flame retardant effect after special treatment. Even if it is ignited by an open flame, it can self-extinguish in just a few seconds to prevent the flame from continuing to spread. The flame retardant performance meets the requirements of the German rail transit industry DIN 5510 standard S4 grade, the smoke density SR2 grade when burning, does not produce dripping when burning, meets the ST2 grade, and the smoke toxicity is also in a very low range. The wear resistance is tested according to ISO12947, and it can be rubbed more than 50,000 times without breaking, which can well protect the internal shielding mesh layer and signal line from being scratched.

The inner layer of the shielding sleeve is the shielding layer, which is a mesh layer woven with tinned copper wires, which can isolate and absorb external complex electromagnetic signals and prevent them from affecting the signal transmission of the internal signal lines.

The shielding sleeve is easy to use and simple to operate. During construction, first disassemble the grounding wire sewn on the shielding net, and then use one end of the grounding wire for grounding after installing a terminal of the corresponding specification. The shielding net is made of metal wire, which can be bent at will. In actual use, the signal line (single or multiple strands) is completely wrapped in the shielding net, and the signal line is tightly attached. Finally, wrap the shielding net and the signal wire with the outer fabric. The fabric is assembled with zipper or Velcro, which is convenient and quick. The fabric layer, shielding mesh and grounding wire use advanced stitching technology, which not only ensures the tightness of the stitching, but also is easy to disassemble and install quickly.

中文

中文 English

English

QQ Customer service 1

QQ Customer service 1