With the development of industry and the increasingly serious environmental pollution, the insulation protection of power system substations, especially the insulation protection of old substations, is increasingly important. In substations, pollution flashovers, condensation flashovers, ice-covered trips, short-circuits of small animals, and personal casualties caused by bare busbars often occur. More and more substations choose shielded button bushings for insulation protection.

Comparison of shielded button sleeve and heat shrinkable tube protection:

The use of heat-shrinkable materials for comprehensive insulation protection of substations can reduce the occurrence of such accidents, improve the reliability of power supply systems, and is of great significance to the safe operation of power systems. However, when heat-shrinkable materials are used to transform power system equipment, it is necessary to carry out It is inconvenient to disassemble the equipment during power failure, and the insulating sleeve is not tightly connected to the special-shaped joint, so it is difficult to be fully enclosed, and as the temperature of the busbar increases, its service life will be severely attenuated and decreased. The heat source absorbs moisture seriously, which further damages the insulating properties of the insulating material and may lead to breakdown discharge. In addition, the casing used in the open-air environment is prone to aging, deformation and damage, and has a short service life. It is inconvenient to replace the casing, and the cost is high.

In order to better eliminate the above deficiencies, the shielded button bushing has begun to go deep into the application of the shielded button bushing in the substation to study the shielded button bushing. In 2008, Tangshan Power Supply Company carried out full insulation treatment of dry-type reactors with silicone rubber, and the insulation effect is excellent. Deal with the dry-type air-core reactor equipment in transit, so as to prevent small animals from entering the equipment interval and cause the reactor to be damaged. The artificial short-circuit test proves that the reactor can effectively avoid the interphase short-circuit fire accident caused by the climbing of small animals after full insulation treatment.

Silicone rubber insulating coatings have strong flame retardancy. Insulation materials for power equipment are required to be flame retardant. This product is mainly composed of rubber-plastic blended polymers, and flame retardants with excellent performance are added to make its flame retardancy reach FV-0 level, which meets the flame retardant requirements of power systems.

Silicone rubber insulating sheath has strong aging resistance. The service life of the silicone rubber insulating sheath can reach more than 20 years, which greatly reduces the cost of recoating, the time of power outage and the economic loss caused by the outage.

The silicone rubber insulating sheath has excellent thermal conductivity, which can effectively reduce the temperature of the busbar during operation, improve the current carrying capacity of the busbar, and solve the problems of aging and cracking caused by the temperature rise of the busbar in the heat shrinkable sleeve.

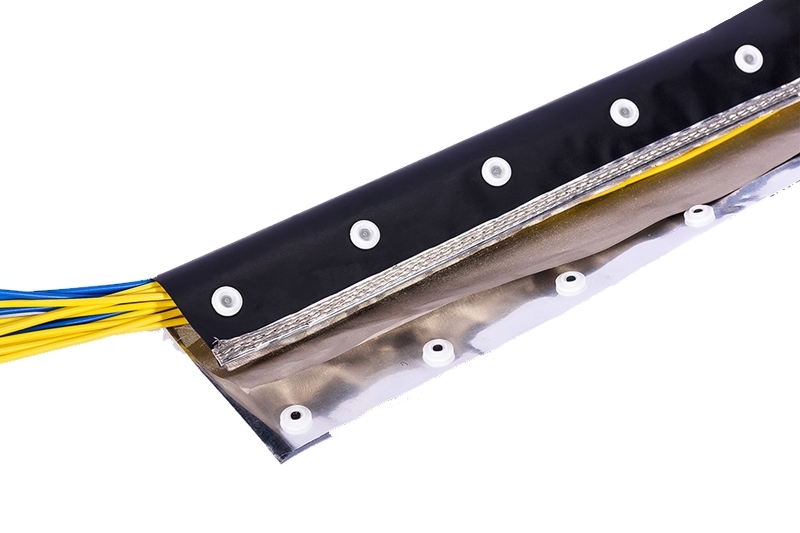

The construction is convenient and fast. The time during the construction of the power system is very limited, which requires the construction work to be simple and fast. The silicone rubber insulating sheath and the busbar are bonded with a silicone rubber adhesive. The silicone rubber adhesive is applied by brushing, and then the silicone rubber insulating sheath can be directly covered. No special tools are required. Generally, one person can The above construction operations can be completed. In addition, the insulating protective covering layer can be manufactured in a factory or constructed on site, thereby saving costs and improving sealing performance.

Silicone rubber insulating sheath has strong insulation. When the power equipment is running, arcs are inevitably generated in the rectifier cabinet. Because the silicone rubber insulating sheath has excellent insulation, the insulation withstand voltage level of the busbar in the power distribution cabinet can be greatly improved, and the air breakdown and insulation voltage drop caused. Short-circuit fault, so as to avoid short-circuit accidents between busbars caused by small animals climbing, and ensure the safe operation of power grid equipment.

中文

中文 English

English

QQ Customer service 1

QQ Customer service 1